Industrial ovens

This is one of the things we do best

We have been manufacturing industrial furnaces since 1952, but then under the name Elvärmedetaljer AB..

We manufacture several types of industrial ovens and it is possible to get them

specially designed according to the needs of your particular company.

Our ovens are suitable in the rubber, plastic, metal, painting industries

and in what other environment you may need an oven.

In today’s automated production flows, it is often required that the goods are picked

in and out of the oven or through the oven.

We have the equipment and competence to help you in this area as well.

Contact us for more information about what we can do for you.

Heating & drying cabinet ovens

A universal heating and drying cabinet for both industrial use and laboratory use in the temperature range 20˚-120˚C, with digital temperature controller and mains connection for 3x400V alternating current and adjustable supply and exhaust air

Convection oven

Convection ovens for vulcanization, curing, drying, etc. available in different sizes with temperatures up to 250 ° C. As standard, our ovens are electrically heated with 70, 100 or 150 mm insulation depending on temperature and thermal conductivity.

The air flow in the oven is adapted to the goods to be processed.

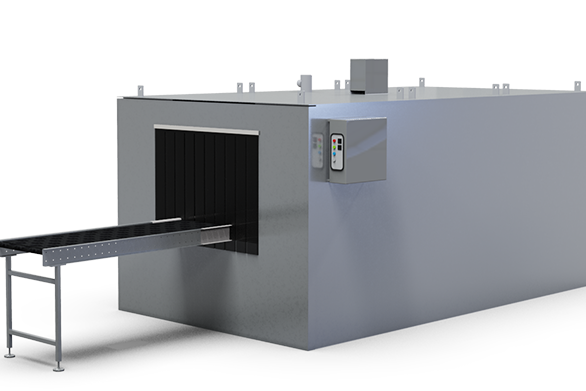

Conveyor oven

Our conveyor oven is often used in applications such as paint drying, adhesive curing, curing and preheating in temperatures from 40 ° C up to 180 ° C. This type of oven uses a conveyor (suspension path) for transporting goods through the oven. The oven has one or more heating zones and can also be delivered with a cooling zone if needed. The oven is equipped with motorized hatches when entering and exiting and inspection hatches along one side of the oven if necessary.

The conveyor furnace is built of a steel frame and is insulated with mineral wool and superwool. The oven is covered with steel plate or stainless steel plate on the inside. One or more fan heating packages are mounted on the roof or wall of the oven to guarantee and ensure high temperature accuracy. Our fan heating packages can easily be equipped with dampers for supply and exhaust air to speed up the cooling process and for diverting dangerous gases such as smoke from oil, etc.

The conveyor oven can be delivered separately or as part of a fully automatic oven line.

All our conveyor furnaces are delivered with complete documentation and CE certificates according to LVD, EMC and the Machinery Directive.

Temperature range: 40-180 ° C

Conveyor / tunnel oven

Our conveyor furnaces are often used in applications such as curing, vulcanization, tempering, annealing, drying, shrinkage and preheating in temperatures from 40 ° C up to 900 ° C. Furnaces of this type use a conveyor to move the load through the furnace and have one or more heating zones.

The temperature can be controlled with a digital controller or PLC system.

The conveyor oven can be delivered separately or as part of a fully automatic oven line.

Temperature range: 40-900 ° C

Ovens with protection gas

Our ovens with protection gas are mainly used in the plastics and rubber industries to harden or vulcanize products.

These ovens are available both as chamber ovens with convection and as top-loading ovens with heat-element technology for placement in-line.

The protective gas used is nitrogen gas and is delivered with complete documentation and CE certificate according to LVD, EMC and the Machinery Directive.

Temperature range: 40-300 ° C.

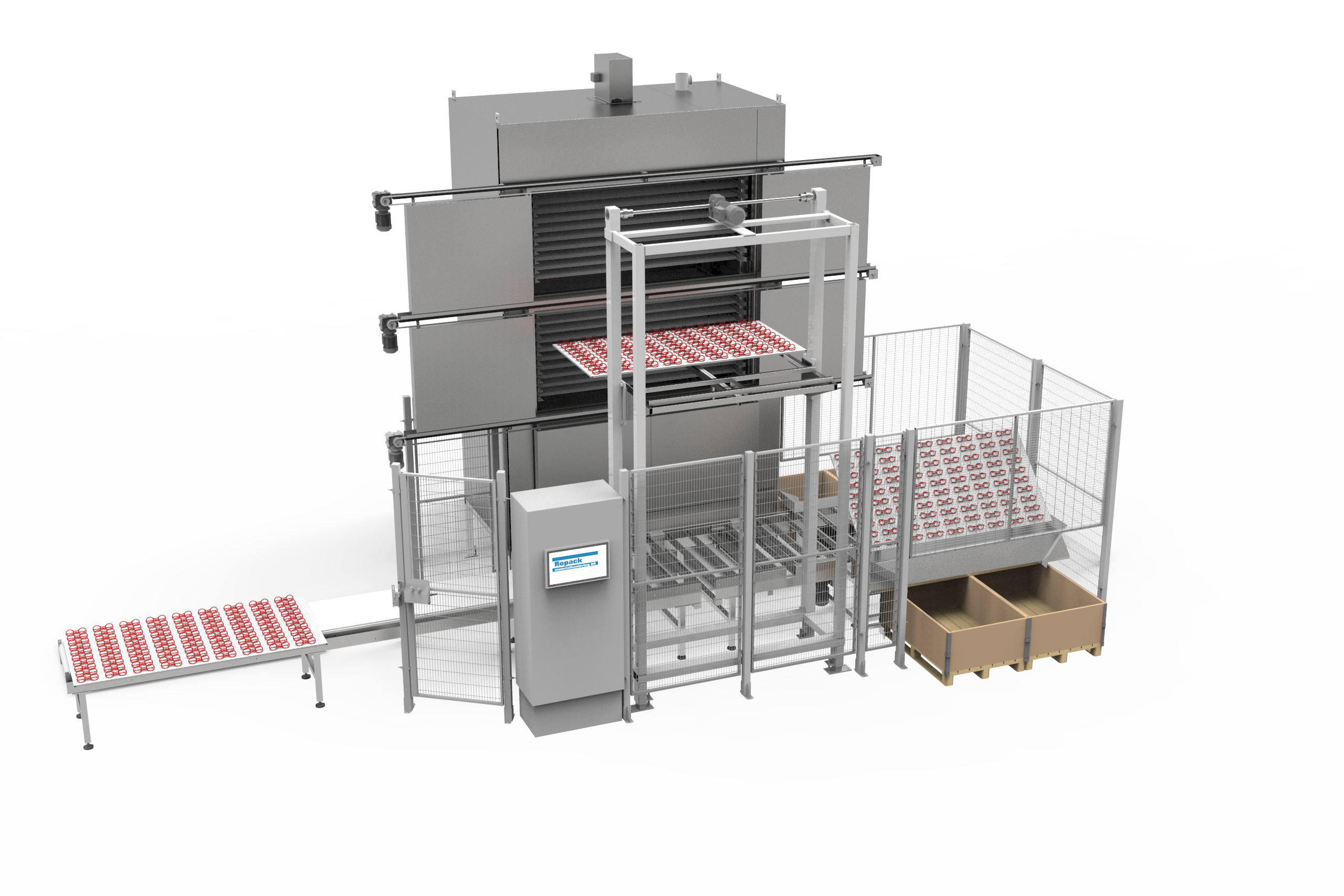

Oven solutions

We design and manufacture complete heat treatment systems adapted to the customer’s needs. Our facilities are optimized to meet all requirements regarding quality, productivity and safety. We help our customers combine productivity with quality by adapting our ovens with the necessary peripherals.

We have the capacity to integrate everything from conveyor systems, handling of robots to refrigeration units and other customized equipment. It all depends on the type of product being heated and what the customer wants to achieve. Contact us for more information on what we can do to increase the productivity of your company.

Let us contac you!